MDS 6 Balance

The MDS 6 Balance is a renowned dosing unit known for its highly accurate gravimetric dosing capabilities and numerous innovative features. Equipped with advanced dosing software, the MDS 6 Balance is able, regardless of vibrations and other deviations caused by the production machine, to accurately measure the ‘loss-in-weight’ of the material in the hopper and automatically adjust the dosing rates, accordingly, resulting in a dosing accuracy of up to 0.02%.

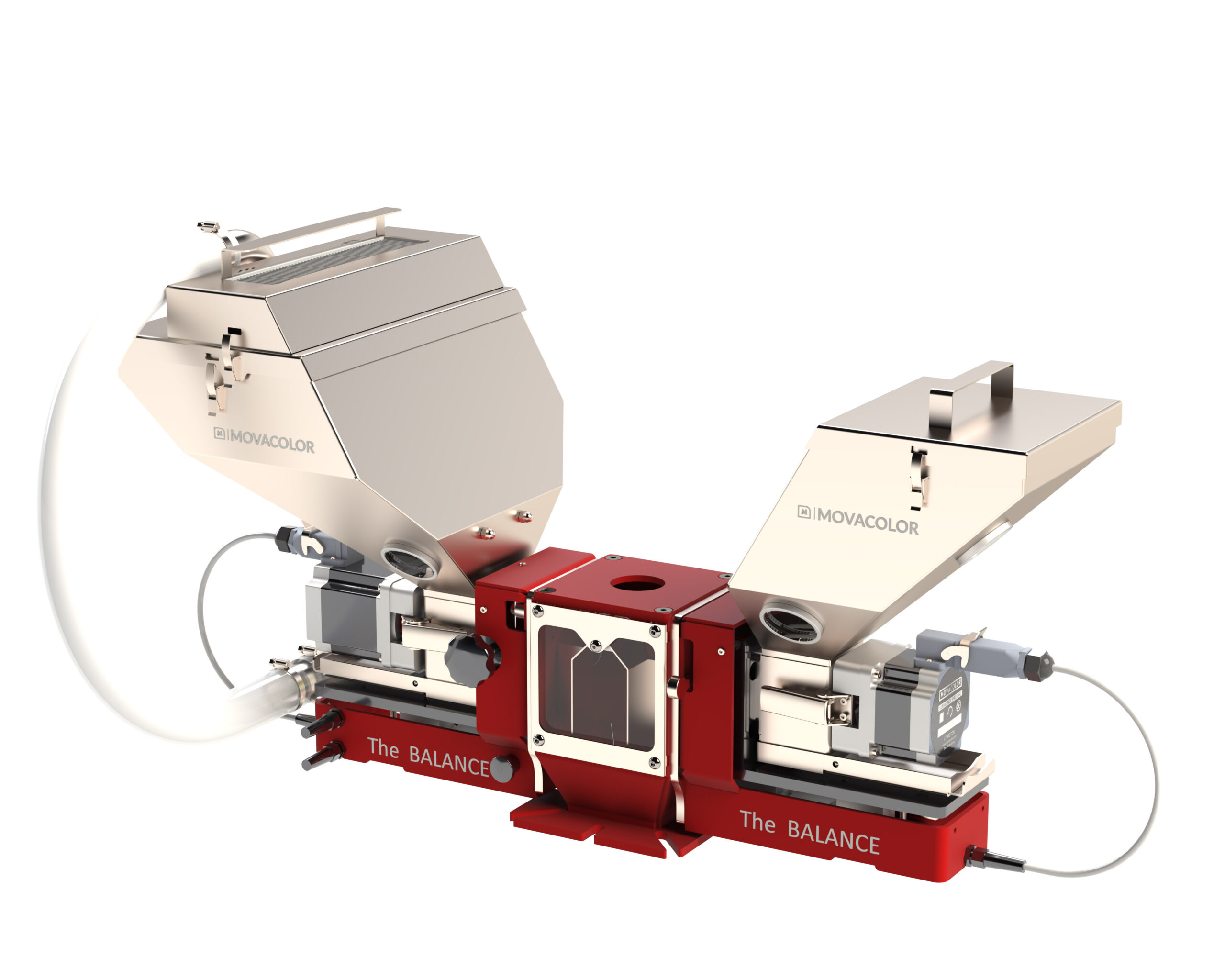

MCS Regrind

MCS Regrind Gravimetric Dosing System, combines two MDS Balance dosing units under one central controller allowing you to accurately dose regrind and color together. The MCS Regrind unit controls both the color and regrind easily utilizing simple percentage settings for each. The MCS Regrind is designed to operate in a closed loop with injection molding, blow molding or extrusion machinery.

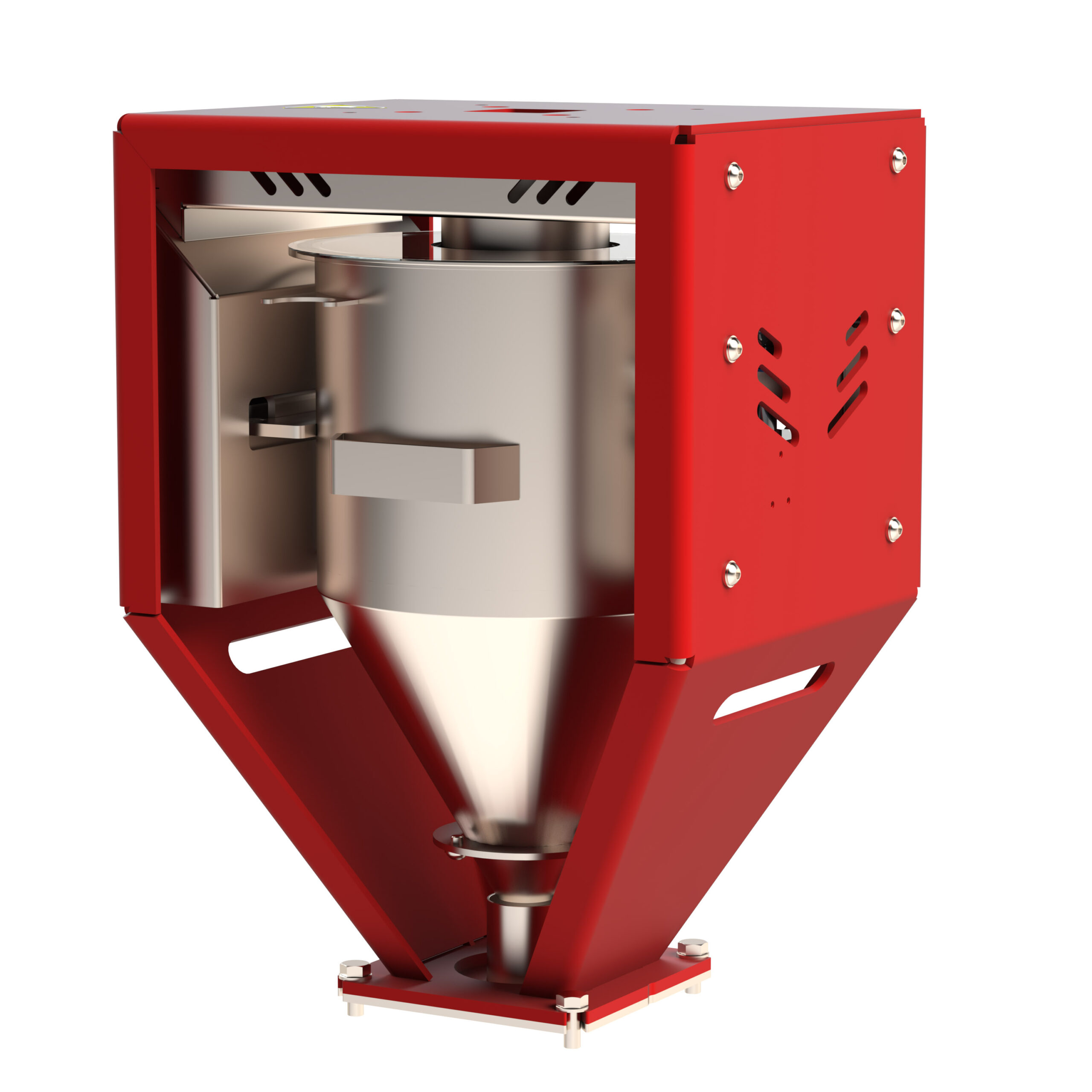

MDS Balance Powder

Dosing powder is one of the most difficult challenges in the field of dosing, especially when we talk about non-free-flowing powders at extreme low rates. Expensive powder additives that add high impact to your process require the best in the field of accuracy and reliability.

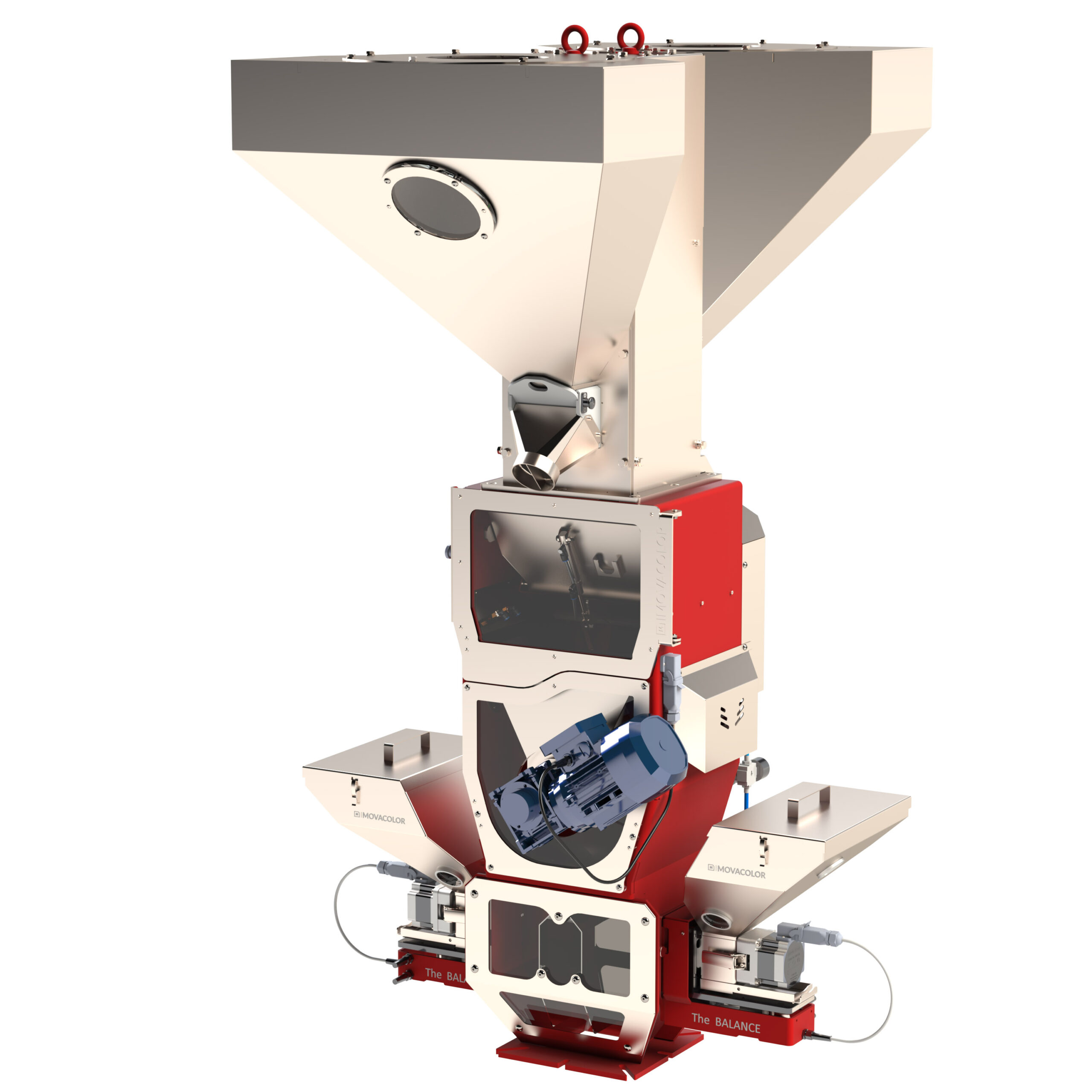

MMS Weight

The MCWeight is specially designed to measure the actual feed capacity of an extruder. It has an integrated weighing module to accurately measure throughput and an integrated knife valve to control the filling. Combined with one or more Movacolor units, the MCWeight tracks even the smallest capacity variation of the extruder. It adjusts the additive dosing from the dosing units accordingly. Dried material with a temperature up to 180°C can be handled with the MCWeight.

MHBS Hybrid Blender

MHBS Hybrid Blender with 2 components; maximum 1600kg/h; touch screen control cabinet incl. input cable, mains power cable, power plug, sensor air-purge. 2x stainless steel 90 liter hoppers with V400,V300 or V200 valves, 20 liter mixer chamber and 6 liter weighing bin; Power supply 220-240 VAC, 50/60 Hz. Power plug and valves to be selected by the customer. Hopper loaders and MDS Balances to be specified by customer - these are excluded from the price.

MDS Balance Liquid Trolley

Coloring with liquid can be a challenging operation. It all depends on reliable dosing, often at extremely low dosage rates. Variation in viscosity of liquids and spill-free handling are the main issues. Movacolor has developed a modular liquid dosing system with one universal motor unit, two pump types and several spill-free packaging concepts. This offers you the possibility of composing your optimum configuration.

MDS Nexus

The revolutionary patented MC Nexus is the new standard for dosing extreme small quantities of masterbatch. It is an ultra-compact dosing unit, able to dose pellet by pellet masterbatch or additives in various shapes and sizes.

MCTC Controller

The MCTC 8 inch touch screen controller plays an important role in the reliability and stability of the dosing process. The robust, easy to start-up (and operate) controller works under all circumstances in injection molding and extrusion applications.